Permeable pavements allow water to infiltrate through surfaces that would normally be impermeable, such as asphalt or portland cement concrete parking lots. (NCDENR, 2007[1]) Rain and snow may then recharge the groundwater table, and air may pass through to nourish the roots of grass and trees. Pervious surface treatments reduce the risk of stormwater runoff, retaining the water sub-surface as it gradually infiltrates the soil; holding the storm water in multiple air voids or cells also assists in pollution control through degradation of hydrocarbons into carbon dioxide and water, and retaining metals in the structure keeps them from the groundwater table. (Hun-Dorris, 2005[2])

Evaporation of water at or below the surface also produces surface cooling, as opposed to the traditional heating of paved areas. This is especially beneficial in cities which experience extremely high temperatures in summer – traditional “blacktop” temperatures can make some public spaces unusable in warmer weather. (Hun-Dorris, 2005[2])

Design of permeable structures generally include a permeable surface such as asphalt or portland cement concrete over a base of fines, which help to filter the water, and uniformly graded gravel, which stores the water as it infiltrates through the ground below the structure. An uncompacted soil base is highly recommended, and construction practices which emphasize this are critical for groundwater recharge. (CRWA, 2008[3])

Permeable pavements excel in the following areas:

- residential

- commercial

- urban

- industrial

- retrofit

However, they are not recommended for:

- highways

- streets

- potential spill sites

- heavy loading

These limitations are due to the fact that in order to allow water to pass through, permeable pavements are not designed with the structural capacity to support heavy loads (Pennsylvania Stormwater Management Manual, 2005[4]).

Porous Asphalt

Porous asphalt, developed about 1970, greatly resembles non-porous asphalt except the fines (very fine sand and dust) have been removed, leaving additional air voids where the fines would have been. This leaves space for water to flow through and collect. Large aggregate is also used to raise the void space. Asphalt is typically designed with a small amount of air voids, typically 4% of the total mix volume, in order to allow the binder to migrate a little. The binder remains somewhat soft long after pavement is laid, and a little moves into these voids, which is called migration. There were problems in the past with early porous asphalt, as the binder would migrate into the higher void spaces, blocking the travel path of the water. This has been ameliorated with the use of additives and additional binders. (NCDENR, 2007[1]; Hun-Dorris, 2005[2])

Additives and additional binders are often used to enhance the characteristics of porous asphalt. Polymers keep the binder from migrating into the void spaces. Polymer-reinforcing fibers assist with cohesion of the mix. (Hun-Dorris, 2005[2])

The appearance of porous asphalt is much the same as non-porous asphalt.

Porous Concrete

Porous concrete, much like porous asphalt, has the fines removed in order to create voids. It was also developed in the 70s. Portland cement concrete (PCC) is typically made with coarse aggregate (gravel), fine aggregate (sand), water, cement, and optional additives. In pervious concrete, the fines are greatly reduced or entirely removed. 15-25% void spaces may be achieved, with an average flow rate of around 480 in/hr. (Hun-Dorris, 2005[2]) The appearance of porous PCC is generally rougher than nonporous.

Finishing during the construction process may create an impervious layer on the surface and attention needs to be paid to the process to prevent this from happening.

Concrete Pavers

|

|

Concrete pavers, or porous paver blocks, are interlocking units which are partially pervious. Water drains through the areas between each block. These spaces can be filled with gravel or grass, and offer drainage and an attractive finish. Infiltration rates tend to be 13-15% of total rainwater (Hun-Dorris, 2005[2])

Paver blocks are typically used in low traffic areas, such as walking paths or driveways.

Turf Reinforcing Grid

Turf reinforcing grid has many different names, including plastic geocells and reinforced turf. Regardless of what you call it, reinforcing gird offers several benefits. The sheets of connected cells stabilize the soil, while holding gravel in place or creating space for grass to grow. (Pennsylvania Stormwater Management Manual, 2005[4])

Reinforced turf in usually used in pedestrian walkways, emergency access lanes, trails, and auxiliary parking.

Other Permeable Pavements

Other permeable pavements include decks, open graded aggregates, and soft paving materials such as wood mulch.

Decks

Decks allow for ease of walking through swampy or sandy areas while creating very low-environmental-impact structures. Wooden structures are also natural looking and aesthetically pleasing.

Open graded aggregate

|

|

Open-graded aggregate is washed to remove fines and is typically made of single-sized, angular pieces. This allows for low settling compaction, and void spaces may constitute up to 40% of the material. Open-graded aggregate is extremely permeable. This kind of base has a strong tendency to segregate and steps must be taken through production, transport, and placement to offset this tendency. Regularly wetting the stone through the laydown and compaction processes keeps the material more stable.

Soft paving materials

Soft paving materials, such as wood mulch and crushed shells, are typically used for foot traffic. High void spaces allow for good permeability, and such materials tend to offer great aesthetic benefits.

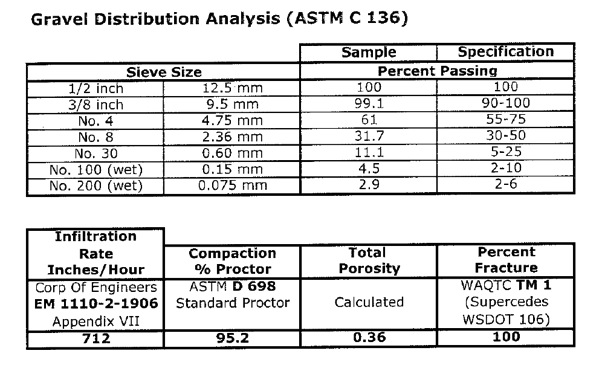

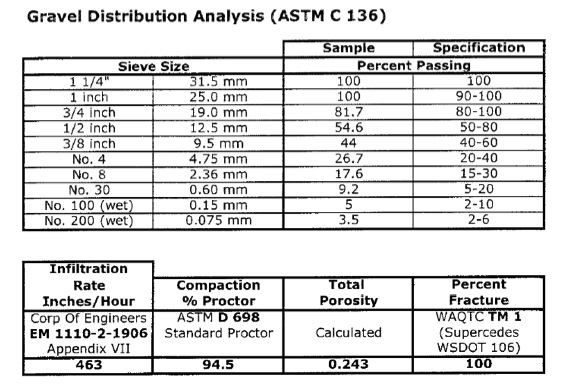

Artificial turf

Artificial turf is typically the topmost layer one or more other permeable layers, such as open graded aggregate. Artificial turf is rolled out in large sheets (see following photos) and pinned to the underlayer. The seams between lengths of turf are stitched. Artificial turf typically lasts for 12 to 15 years. In the Seattle area, Marymoor playfield has an artificial turf surface over 6 inches of open graded base and a 2 inch thick layer of open graded top course. The gravel distribution analysis tables are among the images below.

Benefits

Permeable pavements offer many benefits, both aesthetic and practical. These include: (CRWA, 2008[3])

- Reduces stormwater runoff, including reduction of temperature, total water volume, and flowrate

- Treats water runoff

- Increases groundwater infiltration and recharge

- Provides local flood control

- Improves the quality of local surface waterways

- Reduces soil erosion

- Reduces the need for traditional stormwater infrastructure, which may reduce the overall project cost

- Increases traction when wet

- Reduces splash-up in trafficked areas

- Extends the life of paved area in cold climates due to less cracking and buckling from the freeze-thaw cycle

- Reduces the need for salt and sand use during the winter, due to little or no black ice

- Requires less snow-plowing

- Reduces groundwater pollution

- Creates greenspace (grass groundcover, shade from tree canopies, etc.)

- Offers evaporative cooling

Porous pavements reduce the volume of stormwater, increase the recharge, control the peak rate, and offer a high outflowing water quality. Pollutants are removed: total suspended solids are reduced by 85%, NO3 by 30%, and total phosphorous by 85%. (Pennsylvania Stormwater Management Manual, 2005[4])

Cost

With a permeable pavement system, traditional stormwater systems may be reduced or bypassed entirely. This may reduce the cost of the project significantly. Cost depends on the system chosen, and varies widely. A washed aggregate gravel pathway will be extremely inexpensive and will be permeable at the rate of thousands of inches per hour. (Hun-Dorris, 2005[2]) However, permeable asphalt is more expensive than traditional asphalt. The project specifics also significantly dictate the cost, and must be considered individually. (US EPA, 2000[5])

Some Cost Considerations

(Pennsylvania Stormwater Management Manual, 2005[4])

- Porous Asphalt, with additives, is generally 10% to 20% higher in cost than standard asphalt on a unit area basis.

- Porous Concrete as a material is generally more expensive than asphalt and requires more labor and experience for installation due to specific material constraints.

- Porous Paver Blocks vary in cost depending on type and manufacturer.

Design

The design of permeable pavements varies considerably due to location and cost considerations. However, three things must be considered regardless of which design is being considered: Consider the location and any unique features, local codes, etc.; design a rigorous and correct structure; and build it properly, using best management practices widely available. (Hun-Dorris, 2005[2]) Note that the soil beneath the permeable pavement structure must allow the accumulated water to drain, including special attention to avoiding compaction. Care must also be taken to ensure that debris drains away from the permeable structure, in all directions, to ensure that clogging does not become a nuisance.

Key Design Elements

(Pennsylvania Stormwater Management Manual, 2005[4])

- Surface with significant permeability (> 8” per hr)

- Open-graded subbase with minimum 40% void space (typically a washed aggregate)

- Surface and stone bed suitable for design traffic loads

- Uncompacted sub-grade

- Underlain by nonwoven geotextile

- Level bed bottoms

- Generally not recommended for traffic surfaces with slope >5%.

- Provide positive stormwater overflow from beds

- Do not place bed bottom on compacted fill; fill with stone, as needed

- Protect from sedimentation during construction

- Line bed with nonwoven geotextile

- Provide perforated pipe network along bed bottom for distribution

- Allow 3 ft buffer between bed bottom and seasonal high ground water table and 2 ft for bedrock

- When possible, place infiltration beds on upland soils

Maintenance

Regular maintenance is recommended for permeable pavements. This may include re-sodding, laying gravel, and other small repairs. More typically, maintenance of a permeable structure refers to vacuum sweeping, pressure washing, or air blowing to remove debris. Vacuuming is recommended. (Pennsylvania Stormwater Management Manual, 2005[4]) Depending on the site, this may need to happen 2-4 times a year. Vacuum sweeping for a half-acre parking lot may run about $400-500 per year. (CRWA, 2008[3])

Concerns for maintaining the permeable pavement are typically limited to aesthetics and the prevention/repair of clogging. Proper design may prevent clogging, such as designing for drainage away from the porous section of pavement. This will keep debris from sweeping onto the pavement while allowing rain to infiltrate the soil below.

Special Maintenance Considerations

(Pennsylvania Stormwater Management Manual, 2005[4])

- Prevent Clogging of Pavement Surface with Sediment

- Vacuum pavement twice per year

- Maintain planted areas adjacent to pavement

- Immediately clean any soil deposited on pavement

- Do not allow construction staging, soil/mulch storage, etc. on unprotected pavement surface

- Clean inlets draining to the subsurface bed twice per year

- Snow/Ice Removal

- Porous pavement systems generally perform better and require less treatment than standard pavements

- Do not apply abrasives such as sand or cinders on or adjacent to porous pavement

- Snow plowing is fine but should be done carefully (i.e. set the blade slightly higher than usual)

- Salt application is acceptable, although more environmentally-benign deicers are preferable

- Repairs

- Surface should never be seal-coated

- Damaged areas less than 50 sq. ft. can be patched with porous or standard asphalt

- Larger areas should be patched with an approved porous asphalt

Winter Maintenance

Winter maintenance for permeable pavements is simpler than that for typical pavements. Avoid using any abrasives, such as sand, on or near the porous pavement. Heat retention in the stone bed beneath the pavement tends to provide good snow melt, leading to reduced snow and ice problems. Snow plowing may be used with caution, setting the blade about an inch higher than normal. Salt may be used, however, nontoxic organic deicers are preferred, as the contaminated water will go directly to the water table.

Repairs

Drainage structure repair has the highest priority, in order to keep the system working as designed. Pavement structural repairs will be limited primarily to areas that have settled over soft soils. These areas may be patched with standard or permeable pavement. Potholes will rarely be a problem, due to the lack of a freeze-thaw cycle as in typical pavements. Seal coats ought not be used, as they would nullify the benefit of a permeable pavement.

- North Carolina Department of Environment and Natural Resources (NCDENR). (2007). NCDENR Stormwater BMP Manual. NCDENR. North Carolina.↵

- Hun-Dorris, Tara. (2005). Advances in Porous Pavement. Stormwater.↵

- Charles River Watershed Association. (2008) Low Impact Best Management Practices Information Sheet: Permeable Pavement↵

- Pennsylvania. (2005). Pennsylvania Stormwater Best Management Practices Manual.↵

- United States Environmental Protection Agency (US EPA). (2000). Field Evaluation of Permeable Pavements for Stormwater Management. US EPA. Washington, D.C.↵