Installing, replacing, or repairing underground utilities is one of the most common reasons for patching in pavements, especially in urban areas. Depending on how well agencies manage to coordinate with each other, a perfectly good pavement may need to get torn up on account of utility work. Then when the work is done and the pavement is patched up again, often the patch doesn’t perform as well as the rest of the pavement. In this edition of the RoadReady newsletter, we’ll examine a technique to try and get better performance out of utility patches, the T-section or bridge patch.

Any utility cut, whether it involves a trench for a pipe or cable, or just a smaller “keyhole” opening, will require patching to match the surrounding pavement surface. Fundamentally, a patch will always reduce the structural integrity of the pavement to some degree, even if the patch is installed perfectly. However, many of the problems with patches are due to poor construction practices, so using the right techniques will make a big difference. A properly constructed utility patch should be able to perform comparably to the existing pavement that surrounds it.

The T-Section

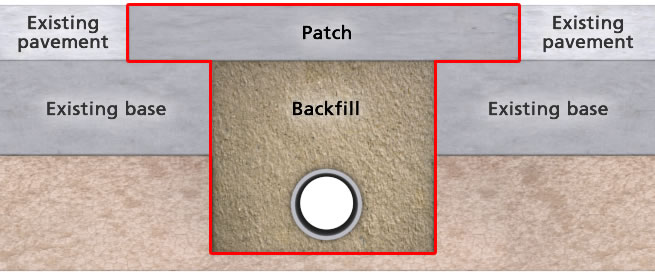

When utility work is completed, the trench must be filled with appropriate base or subgrade material, after which the pavement surface can be patched. One approach that can be adopted is before filling the trench, cut away an additional section of the pavement surface on either side of the trench. The T-section or bridge patch gets its name from the use of this technique.

The advantage of a T-section patch is that it offsets the locations of patch joints in different layers in the pavement structure, and thus prevents a plane of weakness running directly through multiple layers. When an additional section of pavement is removed as part of this technique, a typical distance would be between 6 and 12 inches from the trench sides. After the repair is completed, the pavement patch effectively bridges the utility trench, and the ends of the patch rest on the original base on either side of the trench. When shown in a cross-section, the patch and the trench together form a T shape.

Factors Affecting Performance

Utility patch performance is also affected by many other factors, so achieving a high-quality patch depends on more than just what type of patching technique you use. To make a cost-effective decision, you will want to balance the cost of the work against the expected lifespan of the patch. Proper construction techniques, such as compaction, make a big difference. The joint where the patch meets the existing pavement is also a critical area.

Cost and Service Life

In terms of cost, a T-section patch will naturally add to the expenses for the utility work. Because it involves cutting back (and then replacing) additional pavement material, this technique creates some additional material cost compared with a patch that only covers the trench itself. Whether this cost is justified by the performance benefits is an important question to consider when deciding if this approach should be used. It may also matter who is responsible for actually doing (or paying for) the repair when utility work is done, the utility company or the agency that owns the road.

A related issue is the remaining service life of the pavement when the utility work takes place. This could affect whether it makes sense to use a T-section approach to patching, since the cost of the patch will be weighed against the value to be gained from it. When the remaining life is short, it may not be critical to select the longest-lasting patch technique, and a more temporary patch may be sufficient.

The road-owning agency will naturally be happier if utility patches happen when a pavement is close to a scheduled rehabilitation. This would mean that the patch will likely only be needed for a short time. In addition, if the pavement is ready for rehabilitation, its condition may have deteriorated enough that the patch will actually represent an improvement, at least temporarily.

Compaction

One of the big challenges for utility patches is compaction. This involves not just compaction of the patched surface, but also the underlying base material used to fill the trench. Because of limited space to work in, and the fact that the backfill material may be different from the existing base, it can be difficult to achieve compaction to the appropriate density. Without proper compaction, the life of the patch will be significantly reduced.

Part of the theory in using a T-section or bridge patch is that it allows the patch material to be supported in part by the existing, already compacted base. However, proper compaction of both the backfill material and the patch are essential if the patch is intended to be a permanent repair. A T-section patch will not compensate for inadequate compaction of the replacement base. Soil and subgrade compaction can be verified using a device such as a Dynamic Cone Penetrometer.

Joint Permeability

Utility patches also create a joint where they meet the existing pavement. This opening makes the pavement more permeable and vulnerable to moisture penetration. To some degree, using a T-section patch may help with this problem because water may not penetrate all the way through the pavement structure, the way it could if the joint was directly over the trench walls. Once again, though, the type of patch selected is not as critical as the quality of the patch.

If moisture susceptibility is a concern, then compaction to achieve the desired density at the joint is essential. The joint should also be sealed to keep water and other materials from infiltrating. Without proper compaction and joint sealing, the patch is less likely to perform properly, regardless of the type of patch selected.

Putting It All Together

Ultimately, a quality patch depends on attention to detail. Repairing a utility cut so it can perform as well as the existing pavement requires precise, careful work. One detail to keep in mind is whether to use a T-section patch to mitigate some of the problems with utility patches. As we’ve discussed, following best practices is also critical for projects involving utility work. In order for an approach like a T-section patch to be effective, other parts of the solution need to be in place as well. To make patches that really work, everything needs to work together.

The excavated area, after the placement of utility services e.g pipe etc be not filled with the same material obtained from the excavation. Instead, the area be filled with material that does not required any compactive efforts for densification. Coarse sand with high sand equivalent (96%-100%) is perfect material to be used for refiling the ditch made for placing the pipe etc. With minor viberatory efforts the sand acheives 100 % compaction and does consolidate further with the passage of time and application of repitive loadings.

infrared reheating works great for utility cuts and asphalt repairit. It has been used successfully for many years yet still seems to be an unknown or overlooked method to many industry professionals.

I agree with Ray Riddell as Heatwurx Asphalt Restoration Products and Processes Received “2012 Best in Class” Recognition from AASHTO

http://tig.transportation.org/Pages/default.aspx

you subject has helped me alot in solving real problems with our roads in developing countries.

could i get more on the causes of potholes

See our article on potholes. In general, potholes are caused by load-related stresses and usually start out as fatigue cracking.

Thanks for explaining the T-section patches. I had wondered why they cut more off of the pavement before patching it. However, looking at your diagram of the backfill with the T-section patch I can’t help but wonder if the backfill is the same material used in the existing base. I assume that it is to avoid any problems with the soil settling differently.