Welcome to another edition of the RoadReady Newsletter, where we work hard to ensure that we’re all “Ready to Pave”. In this issue we’ll be discussing something that usually only warrants attention after the fact, when the road is prematurely deteriorating: improper longitudinal joint construction.

Longitudinal joints challenge most of us, since it’s rare to find a pavement without at least two adjacent and parallel HMA mats. Additionally, it’s usually impossible to eliminate the joint altogether, as most situations require you to pave while traffic continues to flow.

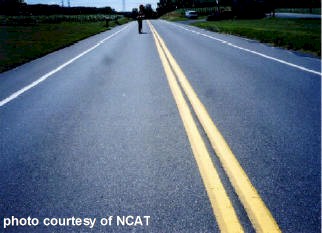

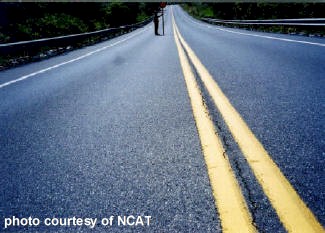

Each time that a crew is laying an HMA mat that requires a joint, they run the risk of making mistakes that could introduce cracking or raveling into the pavement. Below, you’ll see the difference between a properly constructed joint and one that resulted in cracking:

|

Fortunately, these problems can be largely avoided through the use of the proper techniques and equipment. Below are 7 very simple steps that any crew constructing a joint could benefit from knowing:

- Control Segregation at the Outside Edges of the Mat

- Steer a Straight Line

- Compact the Unconfined Edge

- Maintain Correct Overlap

- Place the Proper Depth for Roll Down

- Do Not Lute the Joint

- Compact the Joint for Density