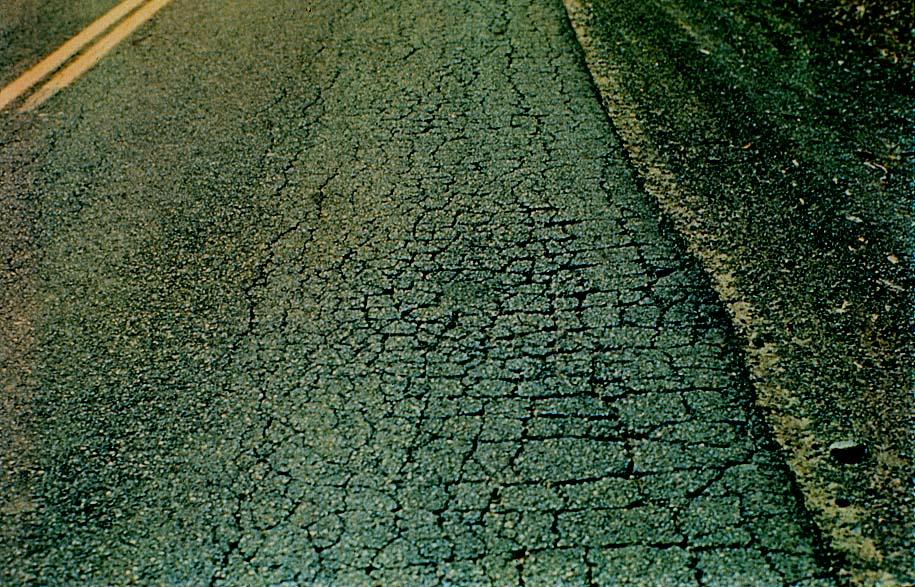

Description

Series of interconnected cracks caused by fatigue failure of the HMA surface (or stabilized base) under repeated traffic loading. In thin pavements, cracking initiates at the bottom of the HMA layer where the tensile stress is the highest then propagates to the surface as one or more longitudinal cracks. This is commonly referred to as “bottom-up” or “classical” fatigue cracking. In thick pavements, the cracks most likely initiate from the top in areas of high localized tensile stresses resulting from tire-pavement interaction and asphalt binder aging (top-down cracking). After repeated loading, the longitudinal cracks connect forming many-sided sharp-angled pieces that develop into a pattern resembling the back of an alligator or crocodile.

Problem

Indicator of structural failure, cracks allow moisture infiltration, roughness, may further deteriorate to a pothole.

Possible Causes

Inadequate structural support, which can be caused by a myriad of things. A few of the more common ones are listed here:

- Decrease in pavement load supporting characteristics

- Loss of base, subbase or subgrade support (e.g., poor drainage or spring thaw resulting in a less stiff base).

- Stripping on the bottom of the HMA layer (the stripped portion contributes little to pavement strength so the effective HMA thickness decreases)

- Increase in loading (e.g., more or heavier loads than anticipated in design)

- Inadequate structural design

- Poor construction (e.g., inadequate compaction)

Repair

A fatigue cracked pavement should be investigated to determine the root cause of failure. Any investigation should involve digging a pit or coring the pavement to determine the pavement’s structural makeup as well as determining whether or not subsurface moisture is a contributing factor. Once the characteristic alligator pattern is apparent, repair by crack sealing is generally ineffective. Fatigue crack repair generally falls into one of two categories:

- Small, localized fatigue cracking indicative of a loss of subgrade support. Remove the cracked pavement area then dig out and replace the area of poor subgrade and improve the drainage of that area if necessary. Patch over the repaired subgrade.

- Large fatigue cracked areas indicative of general structural failure. Place an HMA overlay over the entire pavement surface. This overlay must be strong enough structurally to carry the anticipated loading because the underlying fatigue cracked pavement most likely contributes little or no strength (Roberts et. al., 1996[1]).

- Hot Mix Asphalt Materials, Mixture Design, and Construction. National Asphalt Paving Association Education Foundation. Lanham, MD.↵