Description

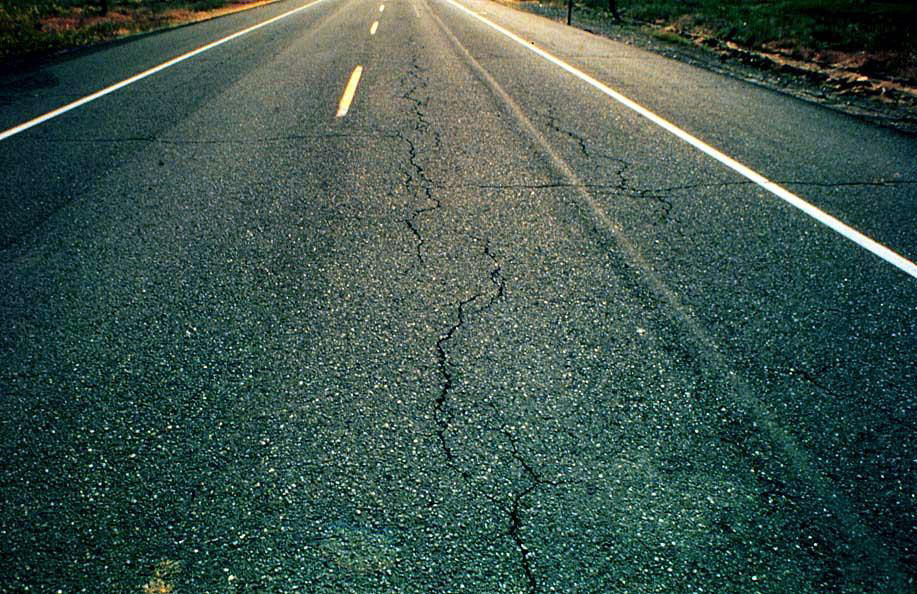

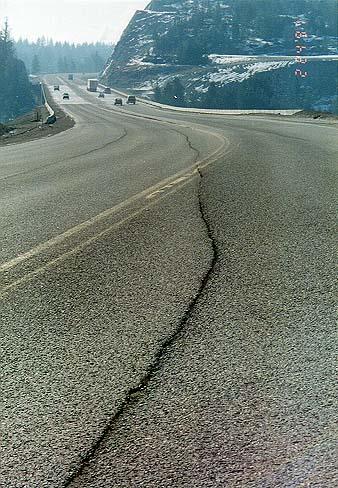

Cracks parallel to the pavement’s centerline or laydown direction. Can be a type of fatigue cracking or top-down cracking.

Problem

Allows moisture infiltration, roughness, and it may indicate the possible onset of alligator cracking and structural failure.

Possible Causes

Poor joint construction or location. Joints are generally the most difficult part of a pavement to compact since it is difficult to position a roller such that it fully compacts the joint without either (1) partially resting its weight on the adjacent pavement (thus bridging over the newly paved longitudinal joint), or (2) missing the newly compacted joint because the roller was not close enough to the edge. If possible, longitudinal joints should be constructed outside of the wheelpath so that they are only infrequently loaded. JFigure 2 and 3 show cracks arising from poor longitudinal joint construction.

A reflective crack from an underlying layer (not including joint reflection cracking). An underlying crack can move slightly, causing stress on an overlying layer and this stress can eventually result in a crack that located right on top of the underlying crack.

HMA fatigue. Often, the first signs of fatigue cracking are longitudinal in or near the wheelpath. This is the onset of future alligator cracking.

Top-down cracking. In pavements of substantial thickness for a given loading, cracking can initiate at the pavement surface (instead of at the bottom of the pavement layer). Cracks initiating at the pavement surface arise from tension induced by wheel loads combined with an aged, more brittle asphalt surface layer.

Figure 4. Longitudinal joint rolling techniques.

Repair

Strategies depend upon the severity and extent of the cracking:

- Low severity cracks (< 1/2 inch wide and infrequent cracks). Crack seal to prevent (1) entry of moisture into the subgrade through the cracks and (2) further raveling of the crack edges. HMA can provide years of satisfactory service after developing small cracks if they are kept sealed (Roberts et. al., 1996[1]).

- High severity cracks (> 1/2 inch wide and numerous cracks). Remove and replace the cracked pavement layer with an overlay.

- Hot Mix Asphalt Materials, Mixture Design, and Construction. National Asphalt Paving Association Education Foundation. Lanham, MD.↵